Cure-in-place-pipeline (or CIPP) repairs are the preferred method for pipeline technicians to fix a multitude of problems within a pipeline without disrupting the land and lives that sit above it. To use the CIPP method for municipal sewer repairs.

Camera Inspection: Two small access holes are drilled into the beginning and the end of the line that needs attention, and a camera is fed in from above-ground where footage is monitored and evaluated. The problem is then pinpointed, and a plan of action is created.

Pipe Cleaning: Before the CIPP process can begin, the pipes must be cleaned and prepped for the process. Hydro jetting is the pipe cleaning method used by the CME team as an environmentally-friendly way to rid the pipes of all debris. The process involves spraying high-pressure water through the city pipes to clear clogs, debris, and tree roots.

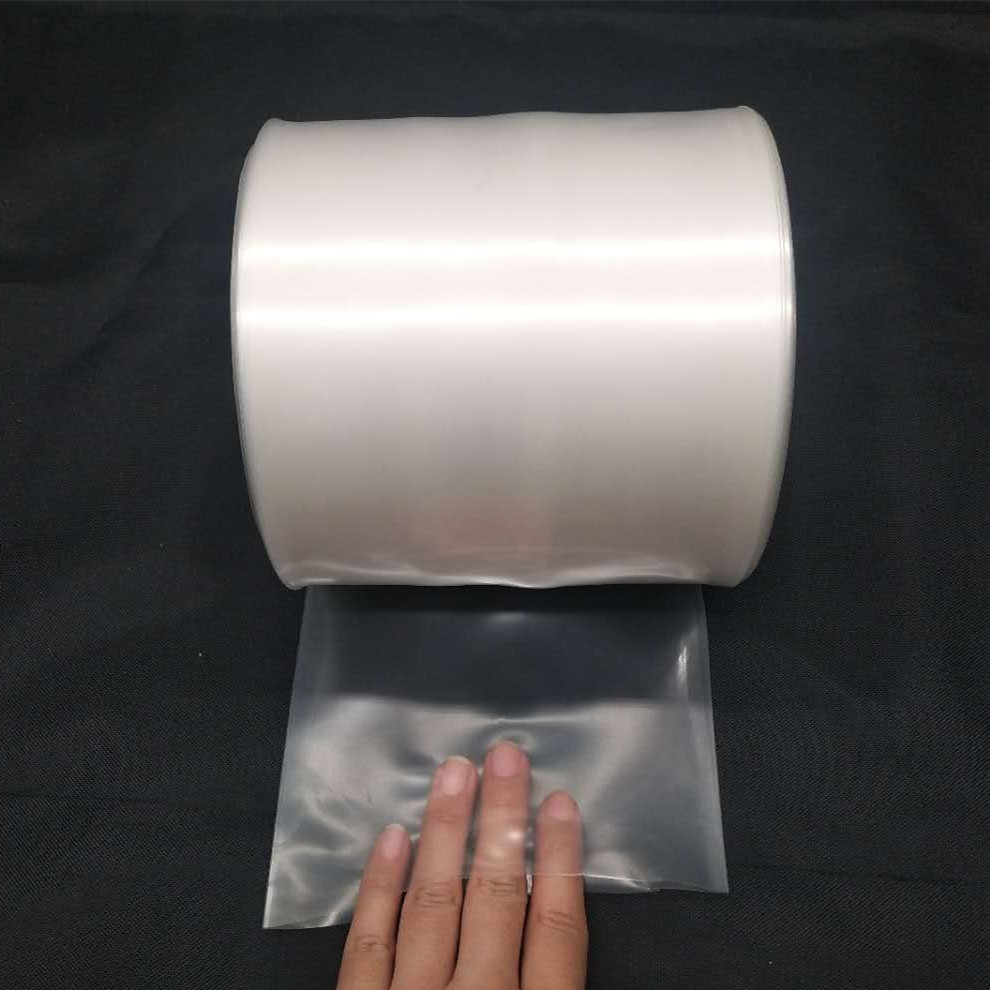

CIPP: Once a follow-up camera inspection confirms the pipes are clean, the CIPP process begins. Technicians use advanced technology to complete the inversion CIPP method, which inverts a pipe whose interior is coated with epoxy resin through the city line, pressing the resin into the interior walls. The resin then creates a new pipe inside the old one, repairing any leaks or corrosion.